ASTM B862 Gr.12 Grade12 Titanium Alloy Square Tube Titanium

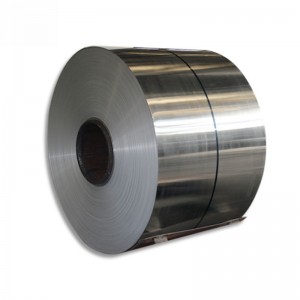

Za a yi bututun da ba shi da sumul na titanium daga bututun billet ta kowane zane mai sanyi ko tsarin rage sanyi tare da ci gaba da kewaye a duk matakan aikin masana'antu.Titanium welded bututu za a yi daga annealed, lebur-birgima faranti ta atomatik baka waldi ko wani walda tsari.

Titanium welded tubes da bututu za a iya amfani da su a cikin masu musanya zafi da kuma condensers, kowane irin lalata ruwa watsa.

tsarin bututun, Titanium bututun keke, bututun shaye-shaye na mota da kiwo na teku, da dai sauransu.

| Rarraba kayan abu | |

| Inconel | Inconel 722, Inconel 725, Inconel X-750, Inconel 625, Inconel 686, Inconel 690, Inconel 702, Inconel 706, Inconel 713C, Inconel 600, Inconel 601, Inconel 601, Inconel 602CA. |

| Incoloy | Incoloy 945, Incoloy A-286, Incoloy 901, Incoloy 903, Incoloy 907, Incoloy 909, Incoloy 925, Incoloy 926, Incoloy 330, Incoloy 800, Incoloy 800H, Incoloy 800H, Incoloy 1,400 Incolo,800 Farashin 208 |

| Hastelloy | Hastelloy C 276, Hastelloy G, Hastelloy W, Hastelloy X, Hastelloy G-30, Hastelloy G-35, Hastelloy G3, Hastelloy N, Hastelloy S, B-2, Hastelloy B-3, Hastelloy C2000, Hastelloy C22 |

| Haynes | Haynes 75, Haynes 244, Haynes 25, Haynes 263, Haynes 282, Haynes 556, Haynes 188, Haynes 230, Haynes 233, Haynes 242 |

| Monel | Monel 400, Monel K-500, Monel R405, Monel 401, Monel 404, Monel 405. |

| Nimonic | Nimonic 91, Nimonic C263, Nimonic PE11, Nimonic PE16, Nimonic PK33, Nimonic 80A, Nimonic 96, Nimonic 90, Nimonic 901, Nimonic 105, Nimonic 115 |

| Sauran nickel | Waspaloy, Multimet N155, Mumetal 80, Rene 41, Kovar, Maraging 250, Maraging 300, Maraging 350, MP159, MP35N, Alloy 46, Alloy 48, Alloy 52, Alloy 42, Alloy 45, Cobalt Alloy 45b, Cobalt Alloy 365b , Invar 42, nickel 200, nickel 201 |

Titanium Tube kamar yadda ASTM B862OD: Welded 6-700mm, Seamless 5-168mm)

MANYAN KYAUTA

Welded: daga 6mm OD zuwa 700mm

Mara kyau: daga 5mm OD zuwa 168mm, har zuwa tsayin 18mtrs

* Ana samun bututu na musamman marasa sumul da bututu a cikin manyan diamita ko ƙarami akan buƙata.

INGANTAWA

Sanyi mirgina, Fitarwa, Welding, Zafafa Fadada

STANDARD

ASME SB861, ASME SB338, ASME SB337, DIN 17861, AMS4943, AMS 4944, AMS 4945, da dai sauransu.

MISALI APPLICATIONS

Bishiyoyin jikin mota mai ban dariya, kulake na golf, masu musayar zafi, layin ruwa, keken hannu, shuke-shuken sinadarai, samar da mai da iskar gas, raket na wasan tennis, sandunan lacrosse, tallafin ramin tuƙi, bututun shaye-shaye, sandunan ƙafafu, masu hana ruwa, masu musayar zafi

| STANDARD | HADIN KASHI (nauyi%, max ko kewayo) | DUKIYAR MIKI (minti) | |||||||||||||

| Saukewa: ASTM B862 | UNS | N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Tashin hankali | yawa | El. | Ja. |

| Mpa | Mpa | % | % | ||||||||||||

| Farashin GR1 | R50250 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | 240 | 138 | 24 | 30 | |||||

| GR 2 | R50400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 345 | 275 | 20 | 30 | |||||

| GR 3 | R50550 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | 450 | 380 | 18 | 30 | |||||

| GR 4 | R50700 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | 550 | 483 | 15 | 25 | |||||

| GR 5 | R56400 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | 895 | 828 | 10 | 25 | |||

| GR 7 | R52400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | 345 | 275 | 20 | 30 | ||||

| GR 9 | R56320 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 620 | 483 | 15 | 25 | |||

| Farashin GR12 | R53400 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.2-0.4 | 0.6-0.9 | 483 | 345 | 18 | 25 | |||

| Farashin GR23 | R56401 | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | 5.5-6.5 | 3.5-4.5 | 828 | 759 | 10 | 15 | |||

Tambaya: Yaya tsawon lokacin isar ku?

A: Gabaɗaya kwanaki 5-10 ne idan kayan suna cikin jari.ko kuma kwanaki 45-90 ne idan kayan ba a hannun jari suke ba, gwargwadon adadi ne.

Q: Kuna samar da samfurori?kyauta ne ko kari?

A: Ee, za mu iya bayar da samfurin don cajin kyauta amma kada ku biya farashin kaya.

Tambaya: Menene sharuɗɗan biyan ku?

A: 30% ~ 50% T / T a gaba, ma'auni kafin kaya ko BL a gani.